BDL REDWOOD - Your Leak Detection Consulting Experts

ABOUT US

Our Team Leader, Jean-Pierre (JP) Deluca (Electronic Engineer) has over 40 years of experience in the leak testing arena (Helium Mass Spectrometry, Hydrogen, Pressure Decay, Pressure Increase, Vacuum Decay and Mass Flow Testing).

JP has worked in numerous roles for leak detection instrument and leak testing equipment manufacturers, specifically as a Product Manager, Applications Engineer, International Leak Detection Director, Sales Director and Vice President of Sales.

JP has extensive experience and expertise in many industries including Automotive, Medical, Pharmaceutical, Refrigeration & Air Conditioning, Semiconductor, Aerospace & Defense, and assisted thousands of customers with their leak testing applications and projects.

Additionally, JP has written many technical articles (see some of them in the “Resources section”) and participated in the writing of many others. He has also presented more than 500 training classes at customer sites and at trade shows.

Jean-Pierre Deluca

Leak Detection Expert

Our mission:

To help customers with existing leak testing systems (improving performance of their systems, assessing and addressing existing technical issues, evaluating and implementing proper calibration and validation procedures, reducing cost of operation, preparing and/or reviewing upcoming customers’ audit).

To assist customers with new leak testing applications and projects (establishing and/or reviewing of the leak testing application leak rate based on application requirements and/or industry standards; Defining and selecting the best leak testing method based on application leak rate requirements and economics; Selecting the leak testing equipment manufacturer; Performing system acceptance at the manufacturer’s site and/or at your installation site).

Educating customers is part of our suite of services as our experience has shown that an educated customer is better prepared to make the right decisions. BDL Redwood leak testing experts offer customized leak testing training (air and tracer gas), from basic to advanced levels; Online or On-site.

IF ANY OF THE FOLLOWING APPLIES TO YOU…

- High helium background resulting in down time.

- Leaks in the system.

- False rejects.

- System calibration issues.

- Test validation issues.

- Poor repeatability and reproducibility of test results.

- Declining cycle times (worsening towards the end of the day).

- High cost of maintenance.

- High helium consumption resulting in increased cost.

- Challenges in keeping up with production due to poor performance of your Helium Leak Testing system.

- Calibration issues.

- Test validation problems.

- Lack of leak testing repeatability.

- False rejections of parts.

- Negative values.

You have been audited by one of your customers and their findings show your leak testing system is not capturing the size of leaks it is supposed to discover.

- The person who oversees your leak testing process has left and you have not trained their replacement.

- You inherited one (or more) leak testing systems and you need to be trained and educated in leak testing.

- Your team has grown and needs to be trained on leak testing (fundamentals and hands-on).

You recently won a major contract requiring the implementation of leak testing processes and you need assistance with your application.

…WE CAN HELP!

See how in the next section “Services” for details.

RESOURCES

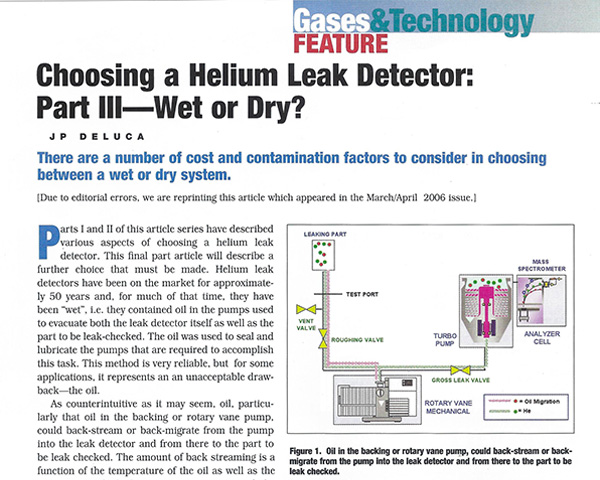

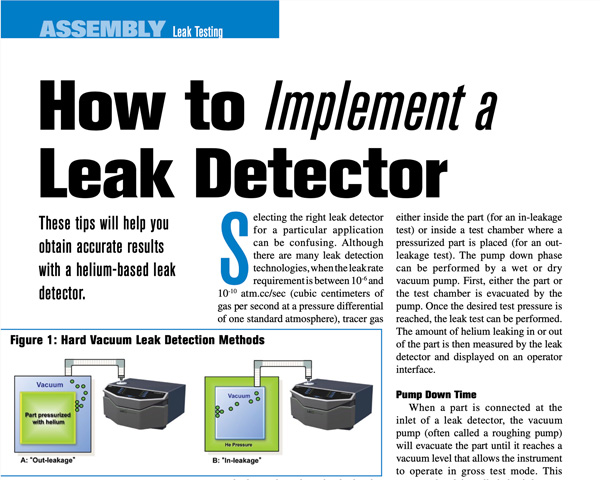

A) Some of Jean-Pierre (JP) Deluca Published technical articles:

B) Converters and calculators

The following first section gives access to many useful tools allowing you to convert:

- Pressure units.

- Pumping speed units.

- Leak rates units.

This section will broaden the user’s arsenal by giving him/her access to the following calculators:

- Pressure decay leak rate (pressure change ΔP as well as corresponding flow rate ΔQ).

- Bubble test leak rate equivalent.

- Tracer gas accumulation.

- Mass loss correlation to volumetric gas leak rate (example: converting a 0.1 Oz of refrigerant into the equivalent gas volumetric leak rate).

- Gross leak rate gas conversion (example: calculating a Gross air leak into a trace gas leak).

- Small leak rate gas conversion (example: calculating a small helium leak into another trace gas leak).

- A gas flow through a capillary.

Please contact us at: jp@bdlredwood.com, to request the password.